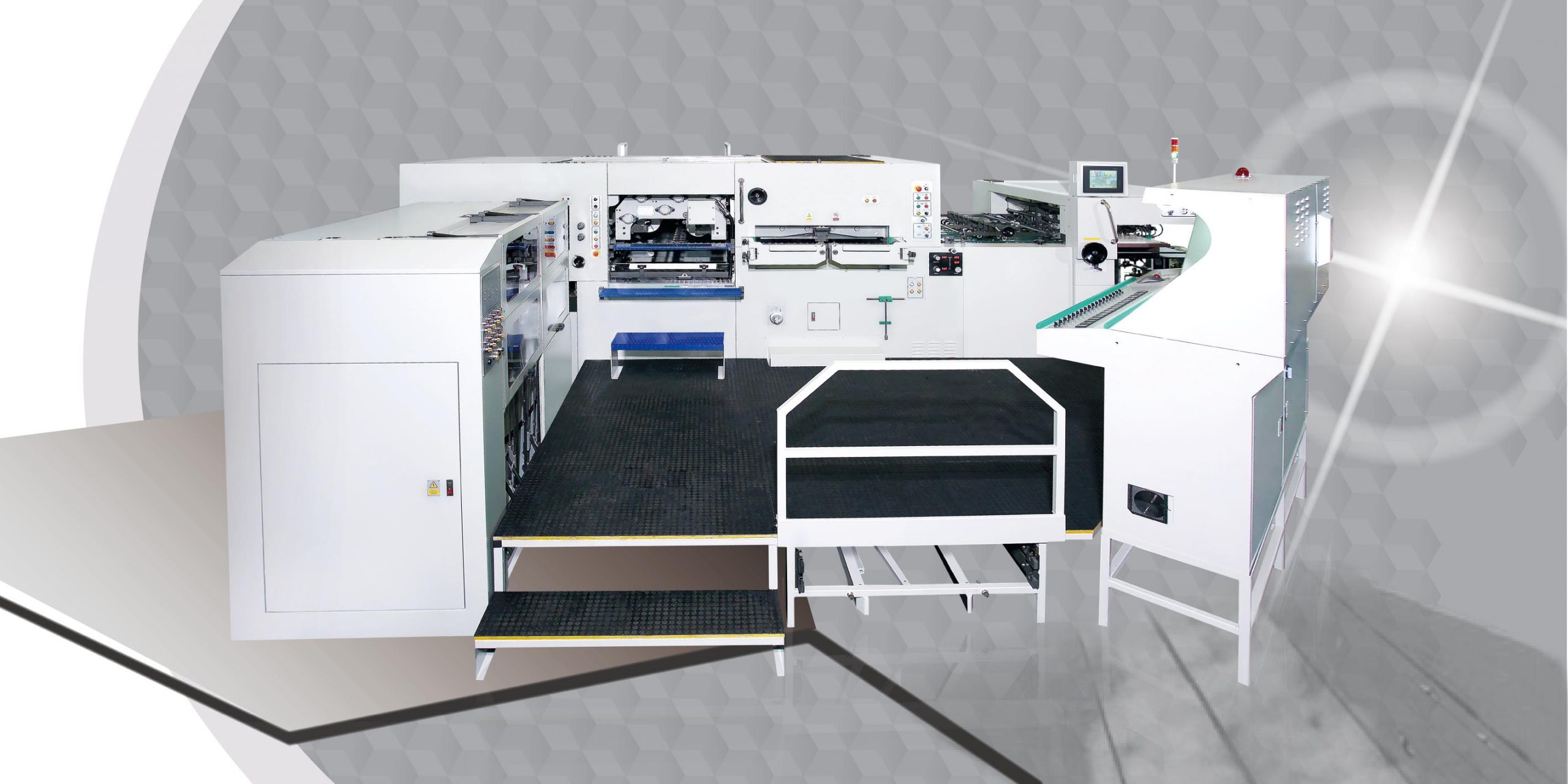

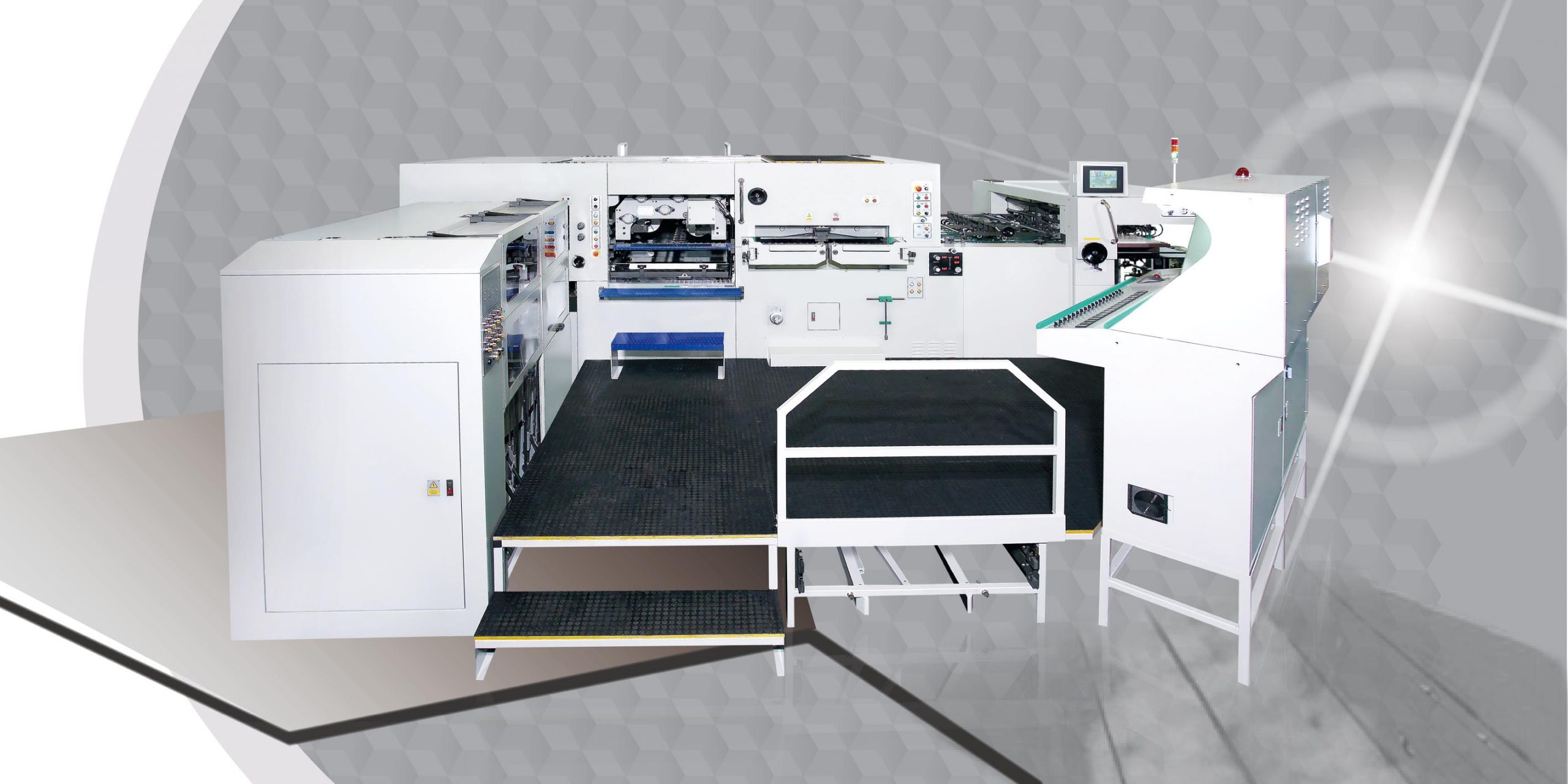

SBL1300EF

Features

- Full colour touch screen HMI. This self-diagnostic system is easy to operate and helpful for troubleshooting any problems throughout each section of the machine.

- Updated and upgraded foil control system, via full colour touch screen HMI. All foil drives have updated, now servo driven on all foil drive shafts, giving improved foil pull accuracy, even at high speed.

- Anvil mounted, 18-zone heater plate, to accurately disperse heat throughout the honeycomb chase, reducing any chance of ‘cool zones’.

- HMI controlled automatic on/off impression system, with tonnage searching program set at low point to avoid machine and foiling die damage. Maximum 500 ton of pressure for both foil stamping and die-cutting.

- Able to run a wide range of stock, from thin paper to B-flute corrugated.

- Sheet transport to front lays monitored and controlled by photoelectric sensors.

- Standard equipment includes operator and drive side push/pull side lay, monitored by micro photoelectric sensors.

- High strength alloy gripper bars to ensure stability at high running speed.

- Pneumatic honeycomb and cutting plate locking system to eliminate loose mechanical parts.

- Standard equipment includes operator and drive side push/pull side lay, with micro photoelectric sensors

- Non-stop feature in both Feeder and Delivery section.

- Motorized brush sheet slow down system gives smooth and accurate delivery, providing precise sheet stacking.

- Options Available;

- Brush rewinding device.

- Pre make-ready table (with modified footprint)

- Full CE safety accreditation.

Specifications

Maximum Sheet Size

1300mm x 950mm

Minimum Sheet Size

600mm x 450mm

Maximum Die-Cutting Paper Size

12900mm x 300mm

Minimum Gripper Margin

9.5mm

Die-Cutting Output Force

500ton

Inner Size of Cutting Chase

1420mm x 958mm

Lower Cutting Plate Size

1328mm x 940mm

Material Handling Range

0.1mm - 2mm 80gsm - 1400gsm

Corrugated Board Range

< 4mm

Recommended Cutting Rule Height

23.60mm

Maximum Cycle Speed

6,500cph

Maximum Operating Speed

6,000sph

Registration Tolerance

+0.075mm

Total Power Requirement

40KvA

Machine Outer Dimensions

L - 6769mm / W - 2444mm / H - 2244mm

Approximate Weight

26ton

Feeder Pile Height (pallet)

1200mm

Feeder Pile Height (non-stop-system)

1400mm